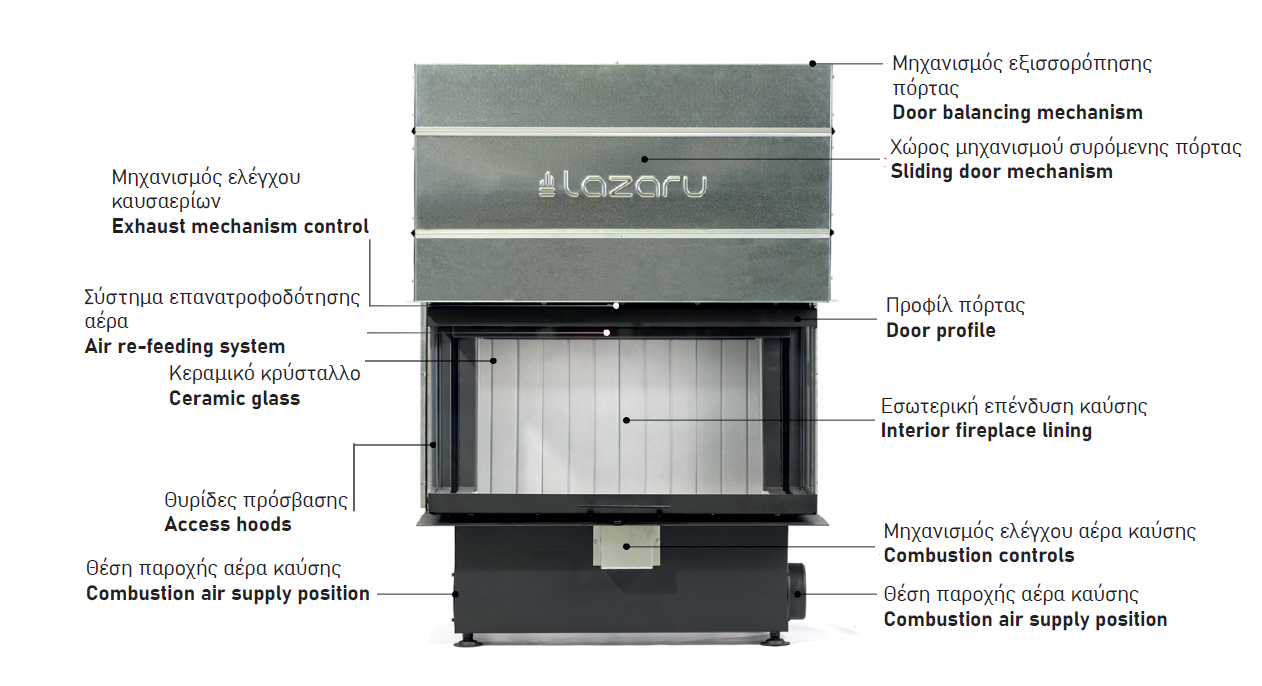

Construction Details

Exhaust mechanism control

The exhaust mechanism control is a simple system for regulating the smoke to the chimney. It is located in a practical place in front and in the middle of the hearth. The lever is constantly cooling because cold air passes through that point. Depending on the choice we make in the lever we reduce or increase the flow of exhaust gases and the efficiency of the hearth.

Combustion controls

Combustion controls are regulated by a steel handle. Combustion control is tightly constructed so that the fire reacts immediately to any choice of air quantity. All combustion checkpoints are fully accessible with visiting boxes. Any temperature change does not affect the operation of the mechanism, due to the materials and the way of construction.

Ceramic glass

The ceramic glass with a resistance of 800ºC helps to reduce the amount of energy that escapes from the combustion chamber to the surrounding space. This makes more efficient management of the heat produced by the hearth. In addition, it helps to secure its space by preventing any sparks, from being found in the surrounding area.

Air re-feeding system

The air re-feeding (secondary combustion) to the hearth is done by openings that exist in the upper middle part of the hearth. This is preheated air that enters from specific paths that heat the air and then push it with pressure to the top of the glass. This helps to clean the glass so that no combustion residues settle but increases the efficiency of the hearth by re-burning the carbon dioxide that did not manage to burn at the bottom of the combustion chamber. Most importantly, it reduces the emission of carbon dioxide into the atmosphere, thus contributing to a cleaner combustion.

Access hoods

The access hoods on the right and left of the hearth make maintaining an easy work in any case of maintain or change parts might be needed. They are in a position to provide the user with the ease of changing rope, adding or removing weight as required.

Combustion air supply position

The combustion air supply position is an innovative system that helps the installer selects the side from which he will bring combustion air from a point that has access to an outdoor area.

Door balancing mechanism

The door balancing mechanism is connected to the sliding door mechanism. It is located at the top of each hearth and consists of four stainless steel bearings that carry the movement up and down the weight of the door. They can be accessed very easily from the top of the hearth, but also from the inside when the hearth is installed. They can be removed in sequence by removing the weight, the ropes, the door and then reposition them in the order in which they were removed. This facilitates that there is no interference in the external investment while the installation of the hearth has been completed.

Sliding door mechanism

The sliding door mechanism is a complete system consisting of durable and precise components that contribute to the smooth rolling of the door but also to its tightness even at high temperatures. The eight bearings slide on a stainless steel profile with precision and stability. It is made in such a way that it presses down on the door and its ceramic cords touch to prevent air ingress. Respectively at the ascent to be removed so that the ceramic cords do not wear out.

Door profile

The door profile is made of 2.5 mm steel with reinforcement of bending pieces that increase the door structure and resistance to deformation even when temperatures rise. Its careful construction increases its lifespan tremendously. At the same time there is an easy space where the ceramic proofing cords are adjusted and their changing during their maintenance will be an easy task.

Interior fireplace lining

The semi-white interior lining of the fireplace chamber, gives special brightness to the combustion chamber, adding finesse to the image of the fireplace, while the dark lining gives a simpler design without standing out in the decoration of the space. The pieces of the dark coating are made of a dark unified mixture which does not deteriorate even when there is accidental damage to the surface. The parts of the combustion lining are made of refractory materials of high strength and quality and are baked at 1200⁰C. This achieves the high mechanical strength of the parts but also the increase of the life time.